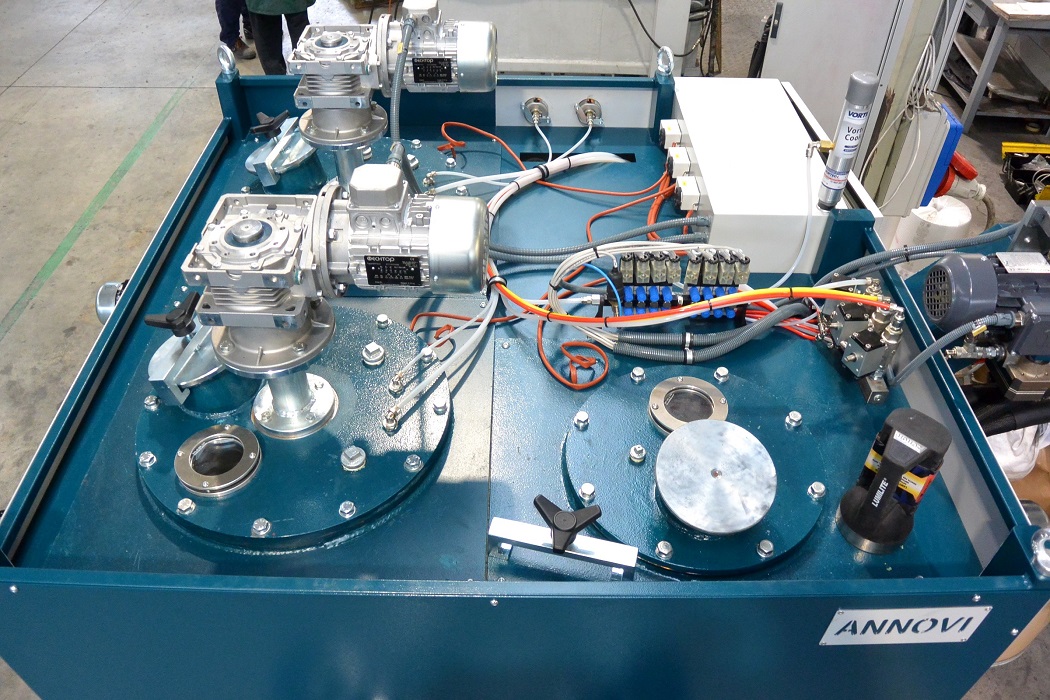

MAIN CHARACHTERISTICS:

- high performance level, able to cast big quantities respecting every wire time of the material

- tanks with interspace for diatermic oil, for rapid heating of the material

- tanks's sized suitable with large scale production

- memorise of recipes, weights, output, colour percentages, mould code and process parameters

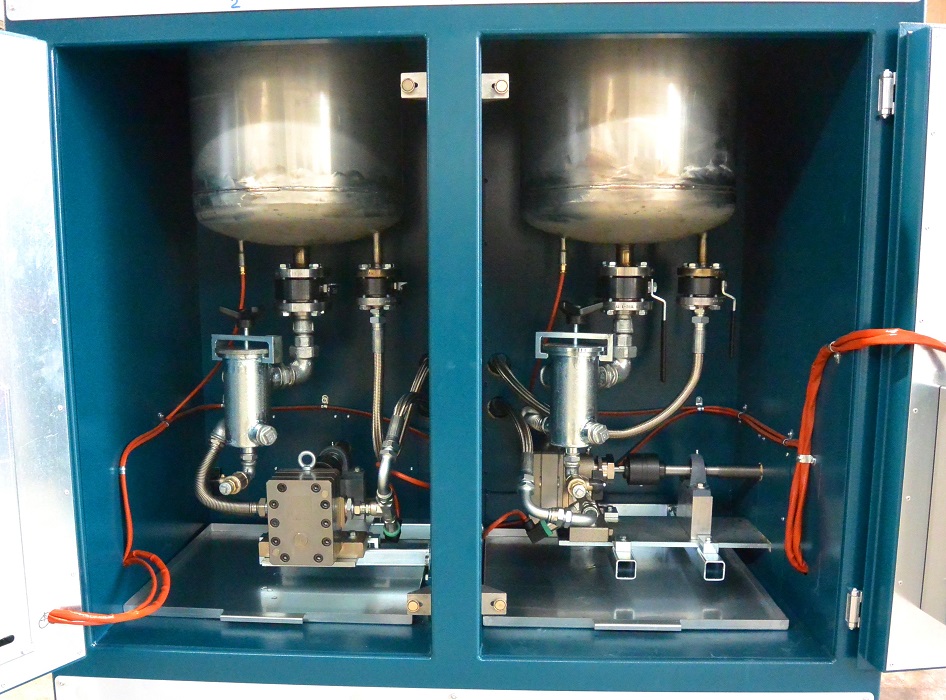

NOVELTY! The new model of casting machine permits to include a INTEGRATE OVEN: into the machine frame has been obtained an heating oven with capacity of two drums (about 25 lt/each), with adjustable temperature until 100°C. That permits to melt the raw material and/or keep the temperature. Part of the heat used by the machine is re-used by the oven and vice versa. This solution has been studied in order to regain and reduce over 50% of energy consumption compared to a layout with separated machine/oven.

If the customer doesn't need the integrated oven, this space can be used at will.

ANNOVI srl provides, over the machine, a service for the customer: after the selling we are available to teach how to better use that and, mainly, to transmit our years' experience.